18 Years Factory In Motion Checkweigher - Fanchi-tech X-ray Machine for Products in Bulk – Fanchi-tech

18 Years Factory In Motion Checkweigher - Fanchi-tech X-ray Machine for Products in Bulk – Fanchi-tech Detail:

Introduction&Application

It is designed to be integrated into line with optional reject stations, the Fanchi-tech Bulk Flow X-ray is perfect for loose and free flowing products, such as Dried Foods, Cereals & Grains Fruit, Vegetables & Nuts Other / General Industries.

The system, which is available with multiple reject options including 64-channel air blasting and multiflap, is capable of offering excellent detection of a wide range of contaminants including all metals, bone, glass, stone and dense plastics, etc.

Product Highlights

1.X-ray system designed for inspection of loose, unpackaged free-flowing product such as nuts, dried fruit, lentils, pulses, poultry and meat

2.Auto parameter setting by intelligent product learning

3.Excellent detection of all metals, bone, glass and dense plastics

4.Built for 24/7 operation with pass key Protective Set-up for added security and control

5.Reject options include Single Flap, Dual Flap, Multi-Flap (4) or 64 channel air blasting rejector

6.Quick release conveyor belt for easy cleaning and maintenance

7.Real time detection with colored contamination analysis

8.Auto-storing of inspection data with time and date stamp

9.User-friendly menus for easy operation

10.USB and Ethernet ports available

11.Built-in remote maintenance and service by Fanchi engineer

12.CE approval

Key Components

● US VJT X-ray Generator

● Finnish DT X-ray Detector/Receiver

● Danish Danfoss frequency converter

● German Pfannenberg industrial air conditioner

● French Schneider electric unit

● US Interoll electric roller conveying system

● Taiwanese Advantech industrial computer and IEI touch screen

Technical Specification

|

Model |

FA-XIS4016P |

FA-XIS6016P |

|

Tunnel Size WxH(mm) |

400×160 |

600×160 |

|

X-ray Tube Power(Max) |

80Kv, 210W |

80Kv, 210W |

|

Stainless Steel304 Ball(mm) |

0.3 |

0.3 |

|

Wire(LxD) |

0.2×2 |

0.2×2 |

|

Glass/Ceramic Ball(mm) |

1.0 |

1.5 |

|

Belt Speed(m/min) |

10-60 |

10-60 |

|

Load Capacity(kg) |

15 |

20 |

|

Min Conveyor Length(mm) |

1300 |

1300 |

|

Belt Type |

PU Anti Static |

|

|

Line Height Options |

700,750,800,850,900,950mm +/- 50mm(can be customized) |

|

|

Operation Screen |

17-inch LCD Touch Screen |

|

|

Memory |

100 kinds |

|

|

X-ray Generator/Sensor |

VJT/DT |

|

|

Rejector |

64 channel air blast rejector or multi-flap rejector, etc |

|

|

Air Supply |

5 to 8 Bar (10mm Outside Dia) 72-116 PSI |

|

|

Operating Temperatures |

0-40℃ |

|

|

IP Rating |

IP66 |

|

|

Material of Construction |

Stainless Steel 304 |

|

|

Power Supply |

AC220V, 1phase, 50/60Hz |

|

|

Data Retrieval |

Via USB, Ethernet, etc |

|

|

Operation System |

Windows 10 |

|

|

Radiation Safety Standard |

EN 61010-02-091, FDA CFR 21 part 1020, 40 |

|

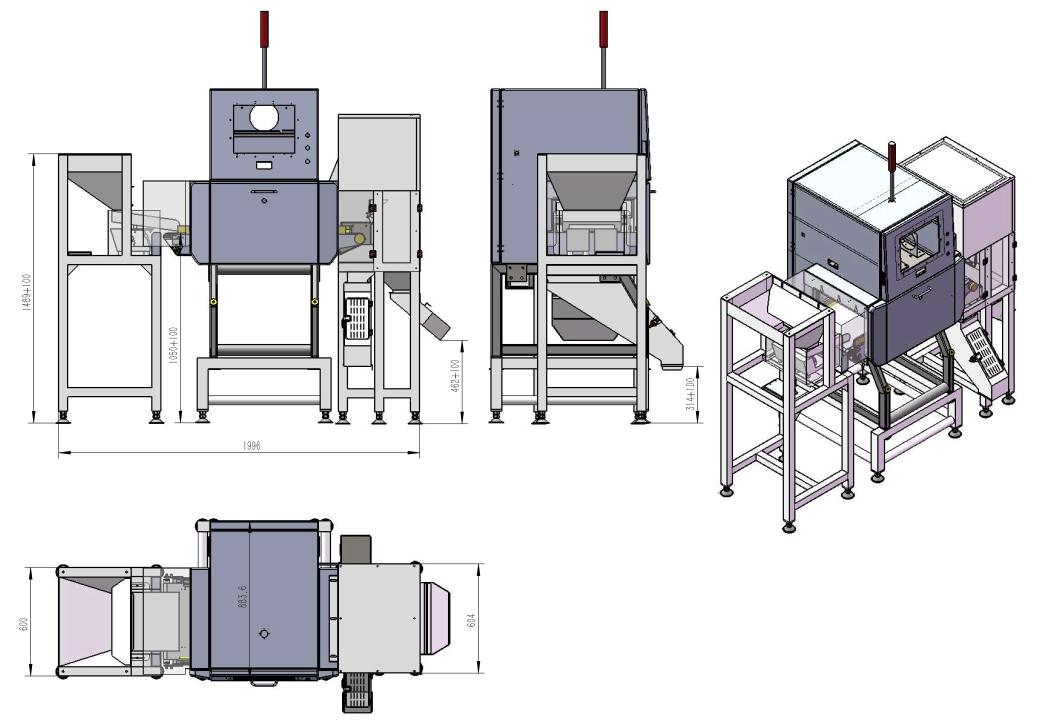

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

The incredibly rich projects administration experiences and a person to 1 service model make the substantial importance of organization communication and our easy understanding of your expectations for 18 Years Factory In Motion Checkweigher - Fanchi-tech X-ray Machine for Products in Bulk – Fanchi-tech , The product will supply to all over the world, such as: United Kingdom, Curacao, New Zealand, Our company insists on the principle of "Quality First, Sustainable Development", and takes "Honest Business, Mutual Benefits" as our developable goal. All members sincerely thank all old and new customers' support. We will keep working hard and offering you the highest-quality products and service.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.