Bottom price Metal Detection For Food Processing - Fanchi-tech Metal Detector for Bottled Products – Fanchi-tech

Bottom price Metal Detection For Food Processing - Fanchi-tech Metal Detector for Bottled Products – Fanchi-tech Detail:

Introduction&Application

Specially designed for bottled prodducts by adding transitional plate, ensure smooth transportation between conveyors; Highest sensitivity for all types of bottled products.

Product Highlights

1.Full range of aperture sizes to suit bottles/jars being inspected.

2.Auto parameter setting by intelligent product learning.

3.Higher interference proof by multi-filtering algorithm and X-R orthogonal decomposition algorith

4.Enhanced detecting stability by intelligent phase tracking technology.

5.Anti-interference photoelectric isolation drive allows remote installation of operation panel.

6.Further improvement in metal sensitivity and detecting stability by adaptive DDS and DSP technology.

7.Storage of 50 product programs by ferromagnetic random access memory.

8.Able to detect all kinds of metal, such as iron, stainless steel, copper, aluminum, etc.

9.Multilevel password protection provides secure access

10.Fall-off proof device for bottle type products.

11.Optional full-cover or open type collecting bin.

12.Optional output safety cover with gate-open sensor that stops the machine.

13.SUS304 frame and major hardware parts by CNC tooling.

Key Components

1. US ferromagnetic random access memory

2. Japanese Oriental motor

3. SUS 304 roller bearing

4. Food grade PU conveyor belt

5. Japanese SMC pneumatic components

6. Danish Danfoss frequency converter

7. Optional keypad and touch screen HMI.

Technical Specification

| Material of Construction | 304 Brushed stainless steel |

| Power Supply | 110/220V AC, 50-60 Hz, 1 Ph, 200W |

| Temperature Range | -10 to 40° C (14 to 104° F) |

| Humidity | 0 to 95% Relative Humidity (Non-condensing) |

| Belt Speed | 5-40m/min(variable) |

| Conveyor Belt Material | FDA approved food level PU belt/Modular Chain Belt |

| Operation Panel | Key Pad(Touch Screen is optional) |

| Product Memory | 100 |

| Rejecting Mode | Sound and light alarm |

| Software Language | English(Spanish/French/Russian, etc optional) |

| Conformity | CE (Declaration of Conformityand Declaration of Manufacturer) |

| Automatic Reject Options | Belt-Stop / Stop On Detect, Pusher, Air-blast, Flipper, Flap, etc |

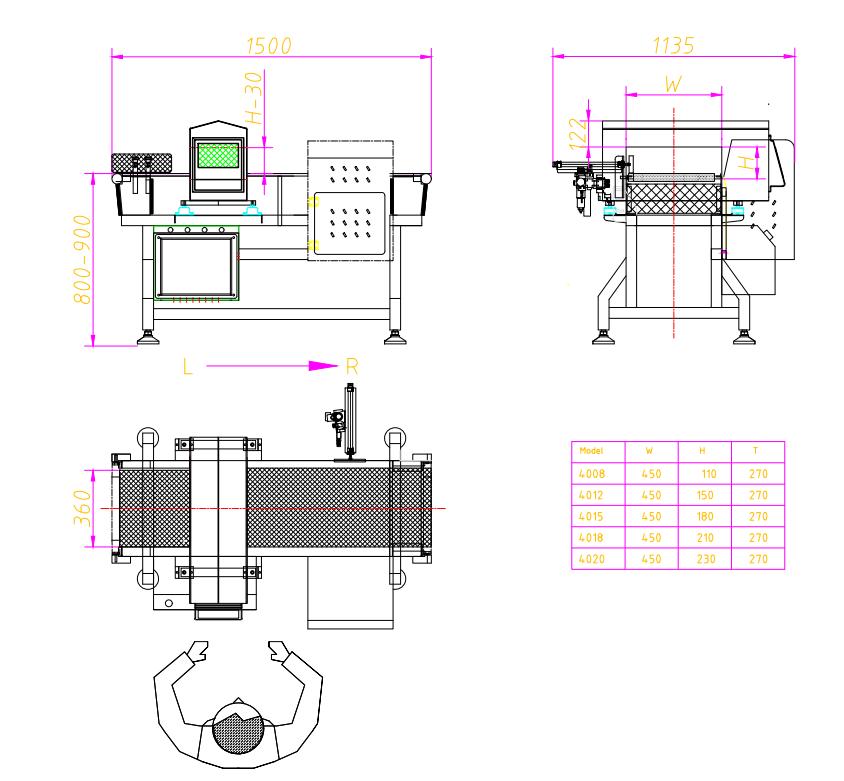

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

The key to our success is "Good Product or service High quality, Reasonable Rate and Efficient Service" for Bottom price Metal Detection For Food Processing - Fanchi-tech Metal Detector for Bottled Products – Fanchi-tech , The product will supply to all over the world, such as: Portugal, Bolivia, Stuttgart, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!