Factory supplied X Ray Checking Machine - Fanchi-tech Dual-beam X-ray Inspection System for Canned Products – Fanchi-tech

Factory supplied X Ray Checking Machine - Fanchi-tech Dual-beam X-ray Inspection System for Canned Products – Fanchi-tech Detail:

Introduction&Application

Fanchi-tech Dual-beam x-ray system is specially designed for the complicated detection of glass particles in glass or plastic or metal containers. It also detects unwanted foreign objects such as metal, stones, ceramics or plastic with high density in the product. The FA-XIS1625D devices use a scanning hight up to 250 mm with a straight product tunnel for conveyor speed up to 70m/min.

The hygienic design with protection type IP66 for the product tunnel makes it particularly suitable for all companies and industries that have to ensure high hygiene standards.

Product Highlights

1.X-ray inspection for food or non-food products and liquids in bottles or jars

2.Detects high density materials like metal, ceramic, stone, plastic and even glass particles in glass containers

3.Scanning height up to 250 mm, straight product tunnel

4.Easy operation with autocalibration and clearly arranged functions on 17“ touchscreen

5.Fanchi advanced software for instant analysis and detection with high accuracy and reliability

6.High speed transversal pusher for glass jars avialable

7.Real time detection with coloured contamination analysis

8.Functions for masking of product parts for better detection of contamination

9.Autosaving of inspection data with time and date stamp

10.User-friendly operation in daily business with 200 pre-set products

11.USB and Ethernet for data transfer

12.24 hours non-stop operation

13.Built-in remote maintenance and service by Fanchi engineer

14.CE approval

Key Components

● US VJT X-ray Generator

● Finnish DT X-ray Detector/Receiver

● Danish Danfoss frequency converter

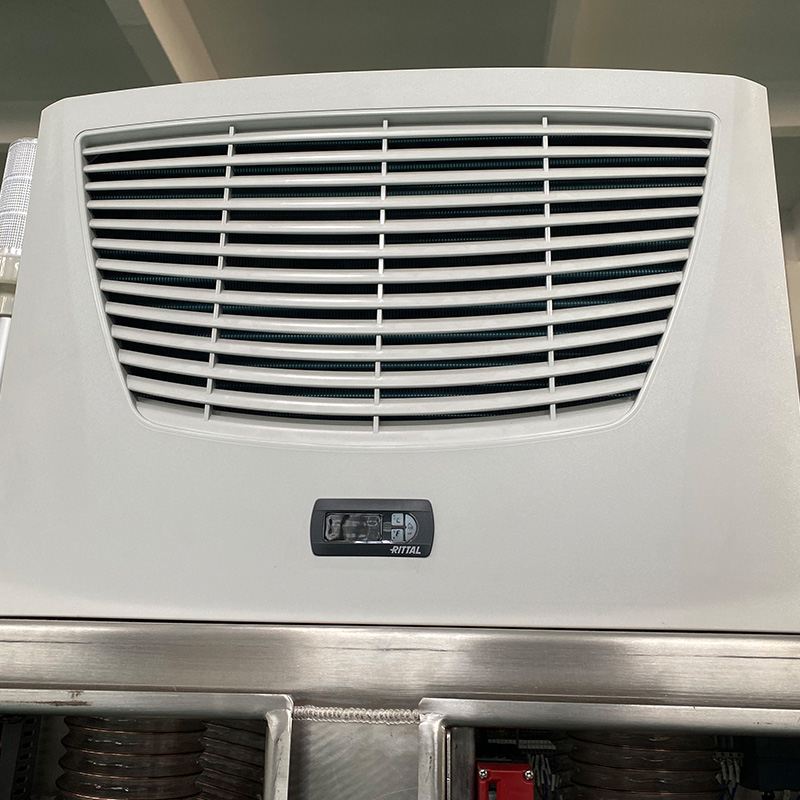

● German Pfannenberg industrial air conditioner

● French Schneider electric unit

● US Interoll electric roller conveying system

●Taiwanese Advantech industrial computer and IEI touch screen

Technical Specification

|

Model |

FA-XIS1625S |

FA-XIS1625D |

|

Tunnel Size WxH(mm) |

160×250 |

160×250 |

|

X-ray Tube Power(Max) |

Single Side Beam: 80Kv, 350/480W |

Dual-beam: 80Kv, 350/480W |

|

Stainless Steel304 Ball(mm) |

0.3 |

0.3 |

|

Wire(LxD) |

0.3×2 |

0.3×2 |

|

Glass/Ceramic Ball(mm) |

1.5 |

1.5 |

|

Belt Speed(m/min) |

10-70 |

10-70 |

|

Load Capacity(kg) |

25 |

25 |

|

Min Conveyor Length(mm) |

3300 |

4000 |

|

Belt Type |

PU Anti Static |

|

|

Line Height Options |

700,750,800,850,900,950mm +/- 50mm(can be customized) |

|

|

Operation Screen |

17-inch LCD Touch Screen |

|

|

Memory |

100 kinds |

|

|

X-ray Generator/Sensor |

VJT/DT |

|

|

Rejector |

Air blast rejector or Pusher, etc |

|

|

Air Supply |

5 to 8 Bar (10mm Outside Dia) 72-116 PSI |

|

|

Operating Temperatures |

0-40℃ |

|

|

IP Rating |

IP66 |

|

|

Material of Construction |

Stainless Steel 304 |

|

|

Power Supply |

AC220V, 1phase, 50/60Hz |

|

|

Data Retrieval |

Via USB, Ethernet, etc |

|

|

Operation System |

Windows 10 |

|

|

Radiation Safety Standard |

EN 61010-02-091, FDA CFR 21 part 1020, 40 |

|

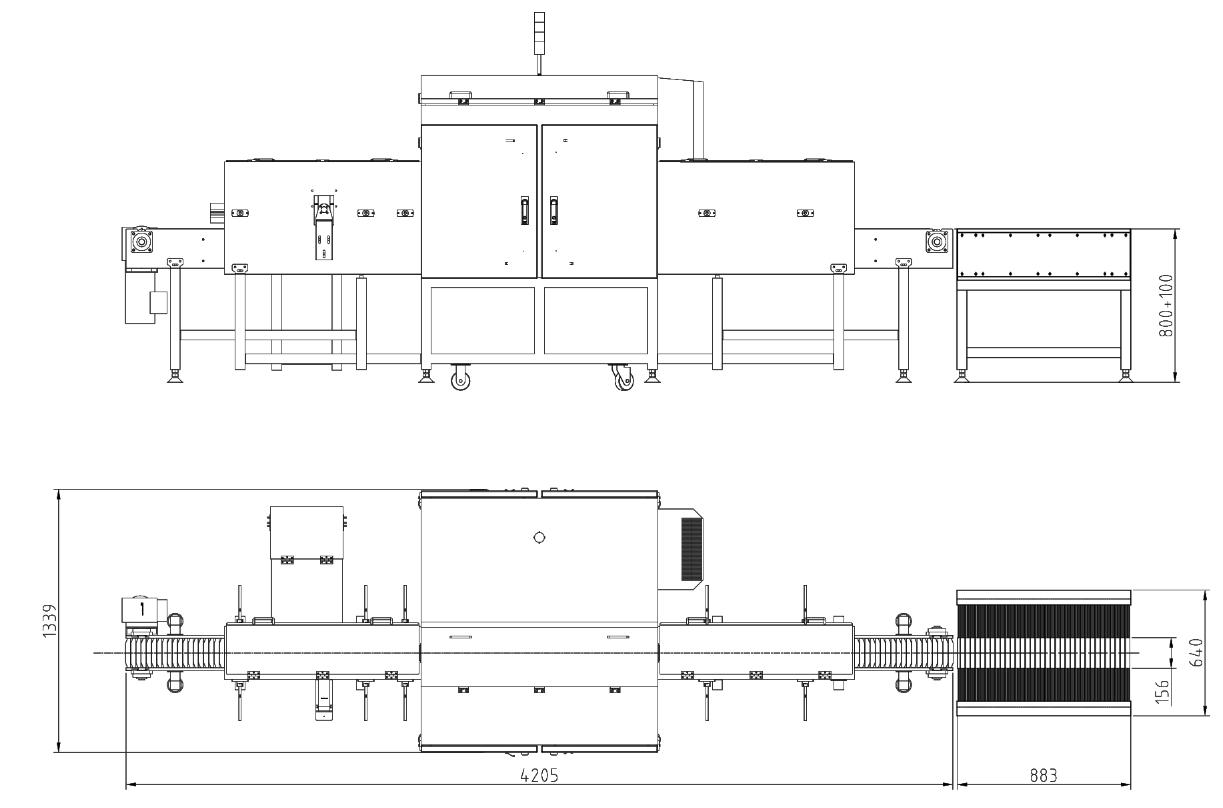

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

We enjoy a very good reputation among our customers for our excellent product quality, competitive price and the best service for Factory supplied X Ray Checking Machine - Fanchi-tech Dual-beam X-ray Inspection System for Canned Products – Fanchi-tech , The product will supply to all over the world, such as: Eindhoven, Austria, Sri Lanka, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to supply our clients sincerely with qualified merchandise, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.