Low MOQ for Automatic X-Ray Inspection - FA-MD-B Metal Detector for Bakery – Fanchi-tech

Low MOQ for Automatic X-Ray Inspection - FA-MD-B Metal Detector for Bakery – Fanchi-tech Detail:

Introduction&Application

Fanchi-tech FA-MD-B Conveyor Belt Metal Detector is specially designed for products in bulk(non-packaged): Bakery, Confectionery, Snack Foods, Dried Foods, Cereals, Grains, Fruit, Nuts and Others. The pneumatic retracting belt rejector and sensitivity of the sensors make this an ideal inspection solution for bulk products application. All Fanchi metal detectors are custom-made and can be individually adapted to the requirements of the respective production environment.

Product Highlights

1.Seamless connection between conveyors by German Igus edge transport system.

2.Detector head by hard-fill technology provides stable and high metal sensitivity.

3.Auto parameter setting by intelligent product learning.

4.Higher interference proof by multi-filtering algorithm and X-R orthogonal decomposition algorithm.

5.Enhanced detecting stability by intelligent phase tracking technology.

6.Anti-interference photoelectric isolation drive allows remote installation of operation panel.

7.Further improvement in metal sensitivity and detecting stability by adaptive DDS and DSP technology.

8.Storage of 50 product programs by ferromagnetic random access memory.

9.Able to detect all kinds of metal, such as iron, stainless steel, copper, aluminum, etc.

10.Output drop-end or belt retraction rejection system perfect for large width conveyor.

11.SUS304 frame and major hardware parts by CNC tooling.

Key Components

● Germany Igus blade angle bearing.

● US ferromagnetic random access memory

● Japanese Oriental motor

● SUS 304 roller bearing

● Food grade PU conveyor belt

● Japanese SMC pneumatic components

● Danish Danfoss frequency converter

● Optional keypad and touch screen HMI.

Technical Specification

| Automatic Reject | Flap Rejector |

| Material of Construction | 304 Brushed stainless steel |

| Power Supply | 220-240 VAC, 50-60 Hz, 1 Ph, 400W 110 VAC, 60 Hz, 1 Ph, 400W |

| Temperature Range | -10 to 40° C (14 to 104° F) |

| Humidity | 0 to 95% Relative Humidity (Non-condensing) |

| Belt Speed | 5-45m/min(variable) |

| Conveyor Belt Material | FDA approved food level PU belt |

| Operation Panel | Key Pad(Touch Screen is optional) |

| Product Memory | 100 |

| Rejecting Mode | Sound and light alarm |

| Software Language | English(Spanish/French/Russian, etc optional) |

| Conformity | CE (Declaration of Conformityand Declaration of Manufacturer) |

| Automatic Reject Options | Flap, Pneumatic Retracting Belt, etc |

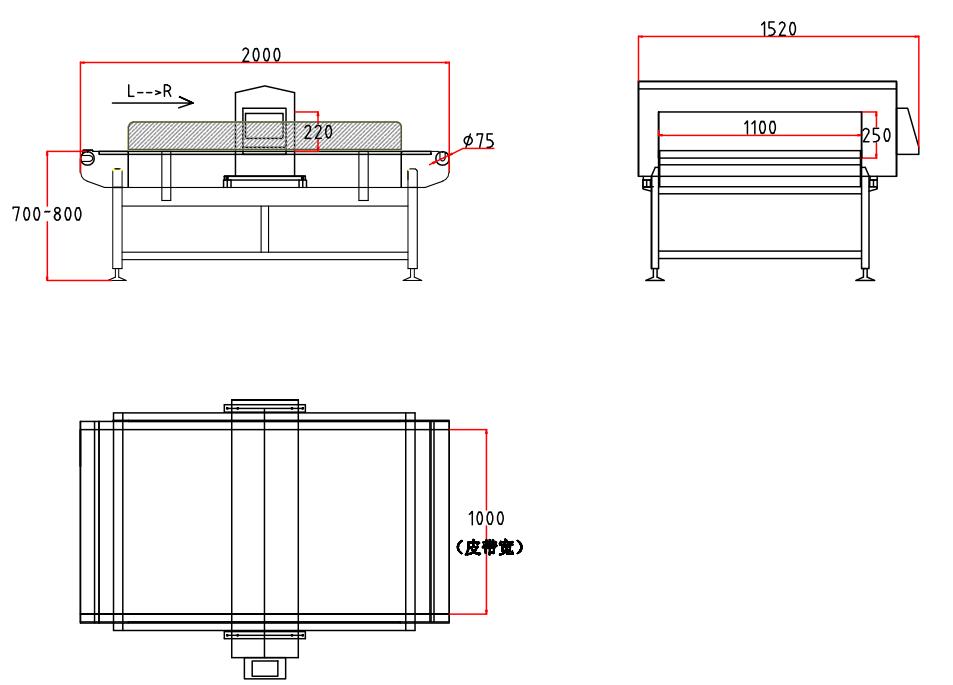

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

With a sound enterprise credit history, exceptional after-sales services and modern production facilities, we've earned an outstanding track record amongst our consumers across the whole world for Low MOQ for Automatic X-Ray Inspection - FA-MD-B Metal Detector for Bakery – Fanchi-tech , The product will supply to all over the world, such as: Bahrain, Guatemala, Niger, As a well educated, innovative and energetic staff,we are responsible for all elements of the research, design, manufacturing, sales and distribution. With studying and developing new techniques,we are not only following but also leading the fashion industry. We listen attentively to the feedback from our customers and provide instant communication. You will instantly feel our expertise and attentive service.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!