OEM manufacturer Fabrication Assembling Service - Fanchi-tech FA-MD-II Conveyor Metal Detector for Food – Fanchi-tech

OEM manufacturer Fabrication Assembling Service - Fanchi-tech FA-MD-II Conveyor Metal Detector for Food – Fanchi-tech Detail:

Introduction&Application

Fanchi Conveyor Belt Metal Detector can be used in various industries: Meat, Poultry, Fish, Bakery, Convenience Food, Ready-to-Go Food, Confectionery, Snack Foods, Dried Foods, Cereals, Grains, Dairy and Egg Products, Fruit, Vegetables, Nuts and Others. The size, stability, and sensitivity of the sensors make this an ideal inspection solution for any application. All Fanchi metal detectors are custom-made and can be individually adapted to the requirements of the respective production environment.

Product Highlights

1. Full range of aperture sizes to suit products being inspected.

2. Auto parameter setting by intelligent product learning.

3. Higher interference proof by multi-filtering algorithm and X-R orthogonal decomposition algorithm.

4. Multilevel password protection provides secure access

5. Anti-interference photoelectric isolation drive allows remote installation of operation panel.

6. Further improvement in metal sensitivity and detecting stability by adaptive DDS and DSP technology.

7. Multiple product memories for rapid product change over and data storage.

8. Able to detect all kinds of metal, such as iron, stainless steel, copper, aluminum, etc.

9. Optional rejection modes: pneumatic pusher, pneumatic flipper, pneumatic drop belt, belt retraction.

10. Optional full-cover or open type collecting bin.

11. Optional output safety cover with gate-open sensor that stops the machine.

12. SUS304 frame and major hardware parts by CNC tooling.

Key Components

1. US ferromagnetic random access memory

2. SUS 304 roller bearing

3. Food grade PU conveyor belt

4. Japanese SMC pneumatic components

5. Danish Danfoss frequency converter

6. Optional keypad and touch screen HMI.

Technical Specification

| Material of Construction | 304 Brushed stainless steel |

| Power Supply | 220-240 VAC, 50-60 Hz, 1 Ph, 400W 110 VAC, 60 Hz, 1 Ph, 400W |

| Temperature Range | -10 to 40° C (14 to 104° F) |

| Humidity | 0 to 95% Relative Humidity (Non-condensing) |

| Belt Speed | 5-40m/min(variable) |

| Conveyor Belt Material | FDA approved food level PU belt |

| Operation Panel | Key Pad(Touch Screen is optional) |

| Product Memory | 100 |

| Rejecting Mode | Sound and light alarm |

| Software Language | English(Spanish/French/Russian, etc optional) |

| Conformity | CE (Declaration of Conformityand Declaration of Manufacturer) |

| Automatic Reject Options | Belt-Stop / Stop On Detect, Pusher, Air-blast, Flipper, Flap, etc |

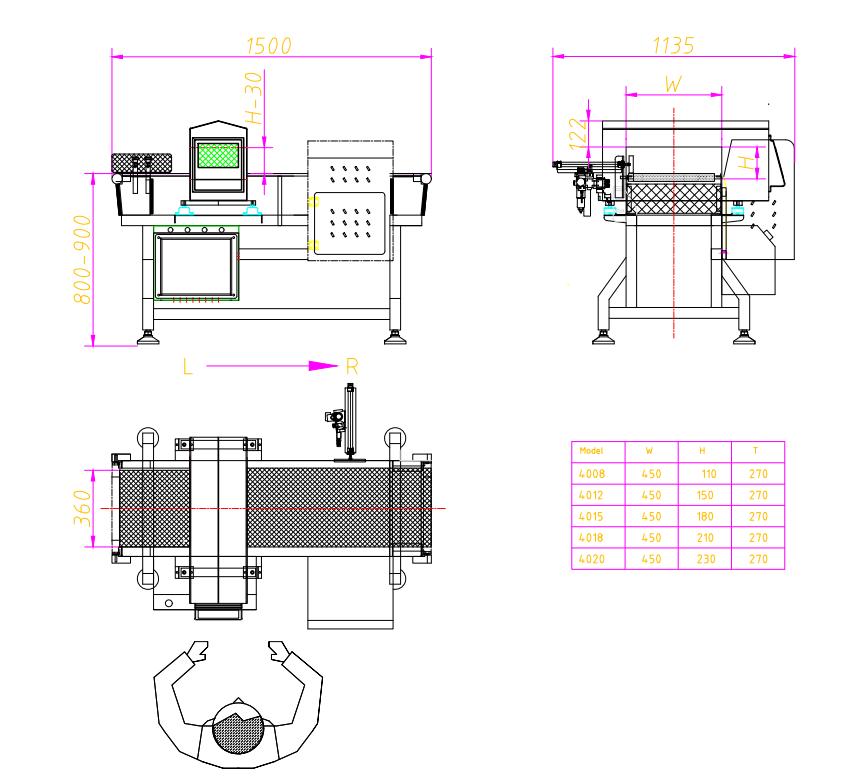

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

Sticking towards the theory of "Super Good quality, Satisfactory service" ,We are striving to become a superb business enterprise partner of you for OEM manufacturer Fabrication Assembling Service - Fanchi-tech FA-MD-II Conveyor Metal Detector for Food – Fanchi-tech , The product will supply to all over the world, such as: Bandung, British, New Orleans, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!