OEM/ODM Supplier Conveyor Metal Detector For Bottles - Fanchi-tech Dynamic Checkweigher FA-CW Series – Fanchi-tech

OEM/ODM Supplier Conveyor Metal Detector For Bottles - Fanchi-tech Dynamic Checkweigher FA-CW Series – Fanchi-tech Detail:

Introduction&Application

Dynamic Checkweighing is a method of safe guarding within the food and packaging industries for product weights. A Checkweigher system will check weights of products whilst in motion, rejecting any products that are over or under the set weight.

Fanchi-tech’s FA-CW range of Dynamic Checkweighers are easy to use with intuitive full colour touchscreens as well as offering fast inspection and product set up, automatically optimising the systems for each product type allowing you to learn and switch within minutes. Our machines are made for products ranging from small and light sachets right through to Heavy weight boxes; They’ve been widely applied in various industries like: meat&poultry processing, sea food, bakery, nuts, vegetables, pharmacy, cosmetics, etc. With a Fanchi-tech checkweigher customized to your specifications, you can depend on accurate weight control, maximized efficiency, and consistent product throughput, even in rugged industrial environments. We will keep your line moving toward maximum productivity at all times.

Product Highlights

1.Accurate and efficient rejection system.

2.Switch Products in Seconds with a Library of Stored Products up to 100.

3.Multilevel password protection for secure access and traceability.

4.Extensive data logging and reporting via USB or ethernet for HACCP and retail compliance.

5.Automatic mean weight correction to help meet weight legislation.

6.Ultra-fast dynamic weight tracking and automatic compensation technology effectively Improve the detection of stability.

7.Brushless motors & proven conveyor components designed for reliable 24/7 operation.

8.For dynamic weighing of large end-of-line packaged goods including convenience foods, sachets and ready meals.

Key Components

● German HBM high speed load cell

● Japanese Oriental motor

● Danish Danfoss frequency converter

● Japanese Omron Optic sensors

● French Schneider Electric Unit

● US Gates synchronous belt

● Japanese SMC pneumatic unit

● Weinview industrial touch screen

Technical Specification

|

Model |

FA-CW160 |

FA-CW230 |

FA-CW300 |

FA-CW360 |

FA-CW450 |

|

Detecting Range |

3~200g |

5~1000g |

10~4000g |

10g~10kg |

10g-10kg |

|

Scale Interval |

0.01g |

0.1g |

0.1g |

1g |

1g |

|

Detecting Accuracy |

±0.1g |

±0.2g |

±0.3g |

±1g |

±1g |

|

Detecting Speed |

250pcs/min |

200pcs/min |

150pcs/min |

120pcs/min |

80pcs/min |

|

Weigher Size(W*L mm)

|

160×200 /250/300

|

230×250 /350/450 |

300×350 /450/550 |

360×450 /550/800 |

450×550 /700/800 |

|

Material of Construction |

Stainless Steel 304 |

||||

|

Belt Type |

PU Anti Static |

||||

|

Line Height Options |

700,750,800,850,900,950mm +/- 50mm(can be customized) |

||||

|

Operation Screen |

7-inch LCD Touch Screen |

||||

|

Memory |

100 kinds |

||||

|

Weigh Sensor |

HBM high accuracy load cell |

||||

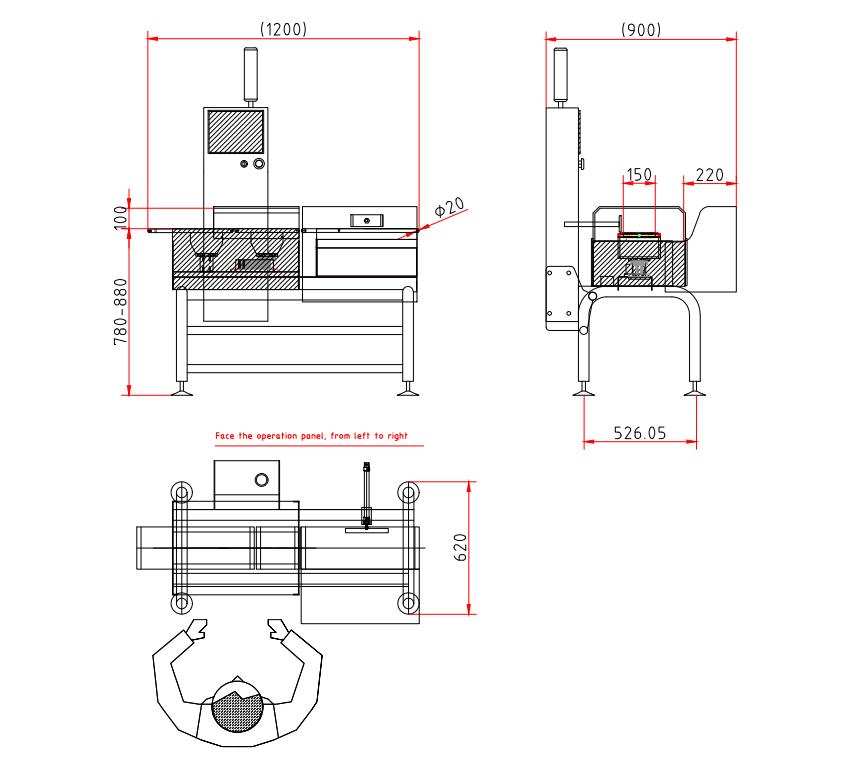

Size Layout

Product detail pictures:

Related Product Guide:

SO KUle

With our loaded working experience and thoughtful products and services, we've got been acknowledged as a reputable supplier for most international buyers for OEM/ODM Supplier Conveyor Metal Detector For Bottles - Fanchi-tech Dynamic Checkweigher FA-CW Series – Fanchi-tech , The product will supply to all over the world, such as: Uruguay, Jeddah, Estonia, Corporate goal: Customers' satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.